Steel Decarbonisation: A Pathway To Development

NSW Energy and Resource Knowledge Hub

18 September 2024 – by Eric Koons

Steel decarbonisation is at the centre of climate change discussions. As one of the most carbon-intensive industries, the steel sector plays a critical role in shaping a sustainable future. Steel is integral to modern life – from our homes to transportation – and its demand continues to grow. However, traditional steel production, which relies heavily on coal, significantly contributes to carbon emissions, making the shift to green steel more urgent than ever.

Both steel producers and industries that depend on steel, such as construction and manufacturing, are under growing pressure to decarbonise. The race to adopt low-emissions steel is accelerating, with companies exploring methods like using renewable energy, hydrogen and electric arc furnaces (EAFs). Reducing the carbon footprint of steel is no longer optional. It’s essential for long-term sustainable development.

Why Steel Decarbonisation Is Important

Steel is vital to countless industries, but its environmental impact poses a serious challenge. As industries aim for net-zero emissions by 2050, decarbonising steel is critical in cutting global carbon emissions. The iron and steel industry accounts for around 10% of total energy system emissions, primarily due to its reliance on coal-powered blast furnaces.

Aside from the direct emissions from steel production, the carbon footprint extends further when you account for the supply chains it feeds. For example, steel is a major component of wind turbines, solar panels and electric vehicles – all critical components of the renewable energy transition. Decarbonising the steel sector will enhance the overall sustainability of many industries.

The Environmental Impact of Traditional Steel Production

Traditional steel production depends on coal-powered blast furnaces, which operate at extremely high temperatures (up to 1,100 degrees Celsius) and consume vast amounts of energy. The reliance on coal as a reducing agent in iron ore smelting further compounds the carbon intensity of steelmaking.

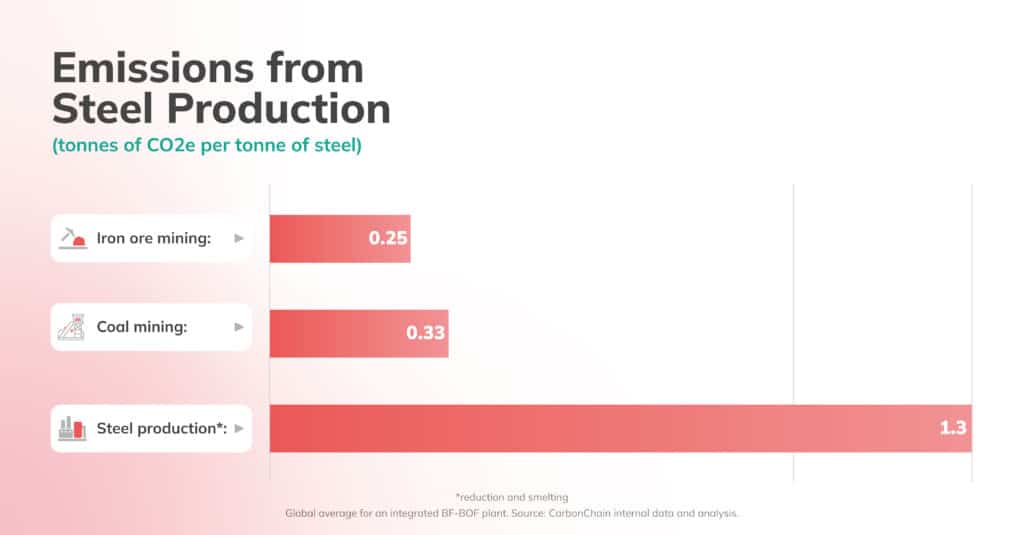

Each tonne of steel produced emits around 1,860 million tonnes of CO2. In 2020, global steel production reached over 1.8 million tonnes, contributing approximately 2.6 billion tonnes of CO2. This not only drives global warming but also exacerbates environmental issues, such as air pollution and habitat destruction from coal mining.

The Decarbonisation Roadmap of Steel Sector

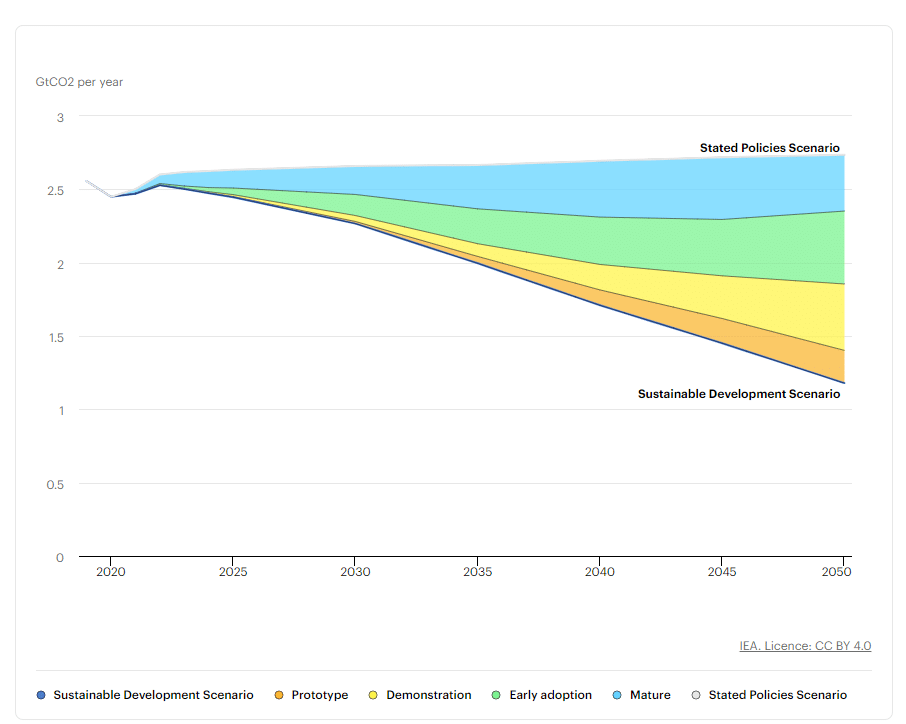

The International Energy Agency (IEA) has developed a roadmap for decarbonising the steel industry, calling for an over 90% reduction in emissions by 2050. However, current trends are insufficient, with the steel sector on track to miss this target without significant technological and policy changes.

The roadmap identifies several pathways, including integrating hydrogen-based steel production, increasing the use of scrap steel in electric arc furnaces (EAFs) and enhancing energy efficiency. Changing policy frameworks and investments in clean energy infrastructure will be critical in driving this transition.

Key Technologies for Steel Decarbonisation

The transition to a low-carbon steel industry depends on several key technologies. EAFs are pivotal in reducing emissions, particularly when powered by renewable energy. Although EAFs account for only about 30% of current steel production, they have the potential to significantly reduce the sector’s carbon footprint. Increased use of EAFs can cut emissions by around 75% compared to traditional blast furnaces.

Green hydrogen-based steel production is another pivotal technology. Using hydrogen as a reducing agent instead of coal can create nearly zero-emission steel.

Carbon capture, utilisation and storage (CCUS) technologies are also critical for decarbonising the sector. These systems capture CO2 emissions from steelmaking and either store them underground or use them in other industrial processes. However, it is imperative to note that research groups have recently criticised CCUS. Transition Asia says, “CCS is not a full-scale decarbonisation option, and it is frequently underperforming”. At the same time, the IEEFA notes that “CCUS will not play a major role in steel decarbonisation.”

Challenges in Decarbonising Steel Industry: The Role of Renewable Energy

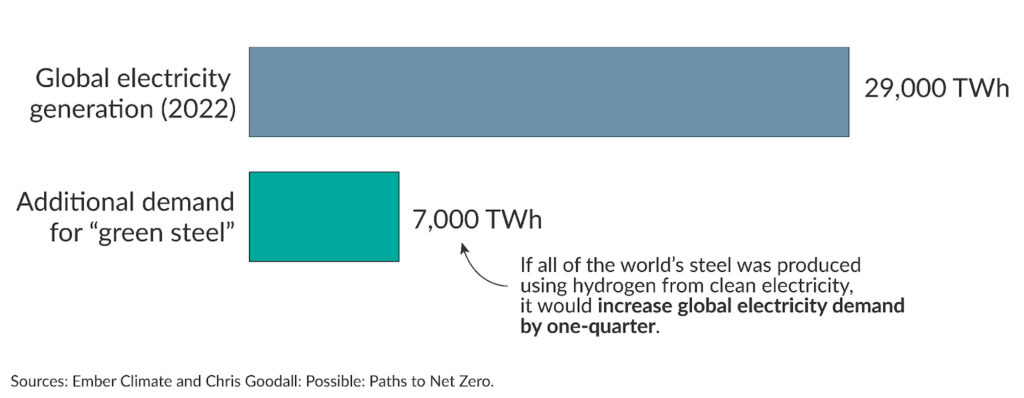

One of the most pressing challenges for steel decarbonisation is the availability of renewable energy. Currently, the steel industry consumes about 8% of the world’s energy, primarily from fossil fuels. To meet the IEA’s decarbonisation targets, the carbon intensity of steel production must fall 60% by 2050, which requires a major shift towards renewables.

For example, with existing technologies, a fully green hydrogen-based steel production economy would require around 7,000 terawatt-hours (TWh) of electricity annually, equivalent to 25% of the world’s current energy demand.

Renewable energy integration is further complicated by the intermittency of sources like wind and solar, requiring investments in energy storage and grid upgrades to ensure reliable power for continuous steel production. Ultimately, decarbonising steel production hinges on the availability of large-scale renewable energy. Without rapid expansion of clean energy infrastructure, the steel industry will struggle to meet its carbon reduction targets.

Pioneers in Green Steel

Several companies and countries are leading the way in producing green steel, which is made with significantly lower emissions. Sweden’s SSAB is one of the pioneers in green steel production. The company has partnered with Volvo to improve hydrogen-based steel production, with plans to scale up production by 2026. Volvo aims to use 25% recycled steel in its new models by 2025 and 100% green steel by 2050.

Germany’s Thyssenkrupp is also improving its hydrogen-based steel production, aiming for carbon-neutral steel by 2045. Similarly, India’s Tata Steel has committed to reducing CO2 emissions and is exploring ways to integrate renewable energy into its production processes, focusing on recycling and energy efficiency improvements.

As these pioneers demonstrate the feasibility of green steel, other companies must follow their lead by investing in renewable energy, circular economy practices and innovative technologies to reduce the industry’s carbon footprint.

Steel Decarbonisation as a Critical Step for Climate Action

Decarbonising steel is essential for cutting global emissions and fighting climate change. As more companies and countries adopt green steel practices, the path to a low-carbon economy becomes more apparent.

However, challenges remain in regions reliant on coal and with limited access to renewable energy. Continued innovation, investment and policy support are crucial to making steel decarbonisation a reality, helping achieve global sustainability goals.

by Eric Koons

Eric is a passionate environmental advocate that believes renewable energy is a key piece in meeting the world’s growing energy demands. He received an environmental science degree from the University of California and has worked to promote environmentally and socially sustainable practices since. Eric’s expertise extends across the environmental field, yet he maintains a strong focus on renewable energy. His work has been featured by leading environmental organizations, such as World Resources Institute and Hitachi ABB Power Grids.

Read more