Hydrogen Production Methods from Fossil Fuels Overshadow Alternatives

18 May 2023 – by Eric Koons Comments (0)

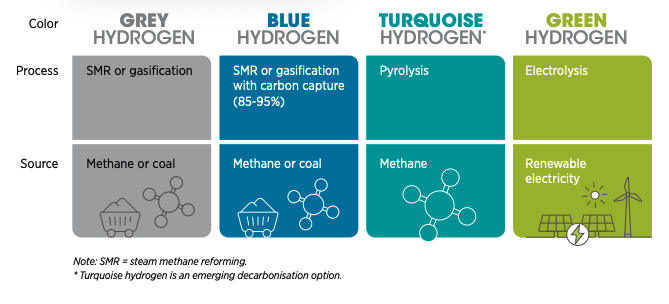

Hydrogen has long been touted as a potential solution to the world’s energy needs, with the ability to provide clean, emissions-free power. However, not all hydrogen is created equal. The vast majority of hydrogen production methods today relies on using fossil fuels. The method contributes to greenhouse gas emissions and uses finite resources.

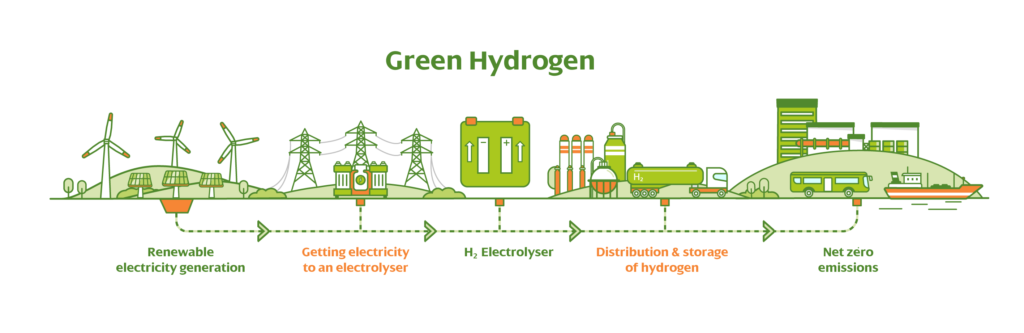

The alternative is green hydrogen, which uses renewable energy sources like wind and solar power. Green hydrogen or renewable hydrogen can significantly benefit the low-carbon energy transition. It provides a clean and sustainable energy source for various applications. This is particularly relevant for hard-to-decarbonise sectors that struggle to rely on standard renewable sources.

The deployment of green hydrogen is still in its infancy, and there is still a lot of work to make it a viable alternative to traditional fossil fuel-based energy sources. Through continued investment and innovation, green hydrogen has the potential to be a key player in the transition to a low-carbon future.

4 Basic Hydrogen Production Methods

There are four hydrogen production methods: steam methane reforming, electrolysis, partial oxidation and biomass gasification.

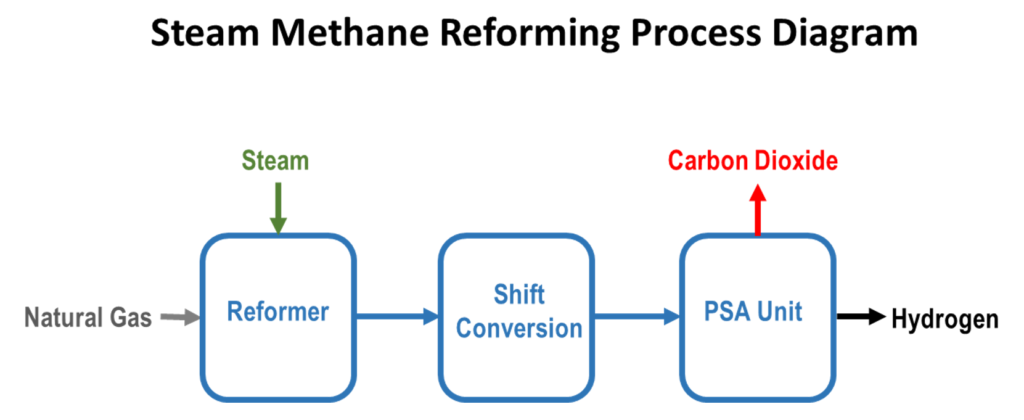

1. Steam Methane Reforming (SMR)

Steam methane reforming or steam reforming is the most common method and involves reacting natural gas with high-temperature steam to produce hydrogen and carbon monoxide.

2. Partial Oxidation

Partial oxidation involves reacting a hydrocarbon fuel with oxygen to produce hydrogen and carbon monoxide.

3. Electrolysis of Water

Electrolysis of water involves passing a current through water to break it into hydrogen and oxygen.

4. Biomass Gasification

Biomass gasification involves heating organic materials, such as wood chips or agricultural waste, to produce gases for hydrogen production.

Each method of producing hydrogen has its advantages and disadvantages, determining its role in the future of low-carbon dioxide.

What Is the Most Efficient Way to Get Hydrogen?

Steam methane reforming (SMR) is the most widely used hydrogen production method and is essential in many industrial processes. SMR is the most efficient method for production of hydrogen due to its high energy efficiency and comparatively low cost.

However, this hydrogen production process is not low-carbon, as it uses natural gas as the base component – a fossil fuel. The reaction generates carbon dioxide (CO2) as a byproduct. This makes SMR reliant on fossil fuels and limits its viability in global decarbonisation efforts.

Despite its carbon emissions, SMR remains a popular method for global hydrogen production due to its efficiency and cost-effectiveness. Additionally, almost all hydrogen infrastructure already in place is for SMR. This is a roadblock to transitioning to low-carbon hydrogen production options.

As the world continues to move towards more sustainable energy sources, there is a growing need for low-carbon SMR alternatives. SMR does not have a place in global net-zero initiatives.

What Is the Greenest Way to Produce Hydrogen?

The greenest way to produce hydrogen is by using renewable energy sources, such as wind or solar power, to power electrolysis. This process uses an electric current to split water into hydrogen and oxygen.

Using renewable energy sources, the carbon emissions from hydrogen production and combustion are nearly zero. The only potential emissions are from indirect sources, like hydrogen storage or transportation.

Developing green hydrogen production technologies is crucial to transitioning towards a low-carbon economy and meeting the growing demand for clean energy.

What’s Holding Green Hydrogen Production Back?

However, as of 2020, green hydrogen accounted for less than 1% of total hydrogen production. The low renewable hydrogen production capacity is due to several reasons that primarily centre around technology and cost.

Hydrogen produced from renewable sources is currently more expensive than other conventional forms of energy like natural gas and coal. This is primarily because it is still produced in small quantities, and the technology has yet to be developed or implemented at a large scale.

There is currently minimal infrastructure for producing, storing, transporting and using green hydrogen. Even in countries where the technology is under development, the number of hydrogen refuelling stations for cars and other vehicles are lacking. Infrastructure development requires a financial commitment, along with committed producers and customers.

Meanwhile, the processes surrounding green hydrogen production still need to be more efficient. For instance, water electrolysis to produce hydrogen requires significantly more energy than SMR.

Other low-carbon technologies like electric vehicles are already established and may offer a more accessible and cost-effective solution to reduce emissions. Hydrogen has a broad range of potential use cases but lacks scale.

While hydrogen has good potential as a clean energy fuel, many people may still associate it with the dangers of compressed gas. However, although the storage and distribution of hydrogen is developing quickly, the technologies are not close to where they need to be.

Making Green Hydrogen Adoption Feasible

The potential for hydrogen to play a significant role in creating a clean, secure and affordable energy future is ripe for the taking.

At the request of Japan’s G20 presidency, the International Energy Agency (IEA) produced a report that explores the current state of hydrogen, highlights its unprecedented political and business momentum and offers guidance for its future development.

The report recommends scaling up technologies and reducing costs to facilitate the widespread adoption of hydrogen. Its practical and feasible suggestions for governments and industry can capitalise on the upward momentum of hydrogen use.

While green hydrogen deployment is not visible to end consumers, there is significant movement in the industrial space, driving technological development in green hydrogen. Over the coming years, it will likely emerge as an important aspect of the global zero-carbon future.

by Eric Koons

Eric is a passionate environmental advocate that believes renewable energy is a key piece in meeting the world’s growing energy demands. He received an environmental science degree from the University of California and has worked to promote environmentally and socially sustainable practices since. Eric’s expertise extends across the environmental field, yet he maintains a strong focus on renewable energy. His work has been featured by leading environmental organizations, such as World Resources Institute and Hitachi ABB Power Grids.

Read more