Ammonia Fuel Engine – Revolutionising Transportation

Source: Shipping Watch

23 August 2023 – by Eric Koons

As the world progresses into the 21st century, the need for sustainable solutions, like ammonia fuel engines, has never been more urgent. Among the sectors scrambling for green alternatives, transportation and energy production stand out, forming a significant portion of global greenhouse gas emissions.

Can Ammonia Be Used to Fuel an Engine?

The reliance on traditional combustion engines powered by fossil fuels is a lingering legacy that demands innovation. While battery electric vehicles are one solution, they are not feasible for transportation. Enter ammonia, a compound of nitrogen and hydrogen, poised to revolutionise the way we power critical industries. Already utilised in manufacturing, ammonia’s transformation into a liquid fuel opens the door to another alternative transportation fuel.

While the prospect of ammonia as a vehicle fuel or part of a dual-fuel diesel engine system is fascinating, it is not without its complexities and challenges. An ammonia fuel engine presents a tantalising glimpse into a low-carbon future, where current engines can be refitted rather than replaced – and efficiency meets environmental responsibility.

How Does an Ammonia Combustion Engine Work?

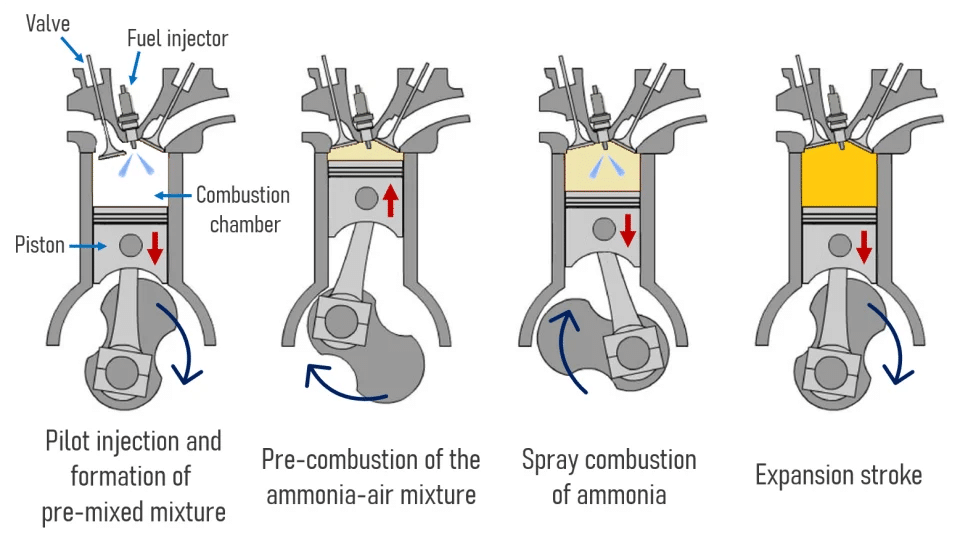

Ammonia combustion engines work similarly to traditional fuel engines but bring unique characteristics that reshape how we understand fuel technology. In a typical ammonia-powered engine, the ammonia fuel is vaporised and ignited, just like in traditional vehicles.

This basic function resembles current fossil fuel engines, but several key differences exist.

- Ignition and Combustion Properties: Ammonia has different ignition and combustion properties in comparison to traditional fuels. It requires a higher ignition temperature, about 651°C, and the flame speed is considerably slower. Modifications to the engine’s ignition system and control of the air-fuel mixture are necessary to optimise performance.

- Integration with Current Technology: Slight changes are needed to cater to the different properties of ammonia, but by and large, they are very similar to current fossil fuel engines. This compatibility means existing fleets can be retrofitted with ammonia-based technology without significant alterations, reducing implementation costs.

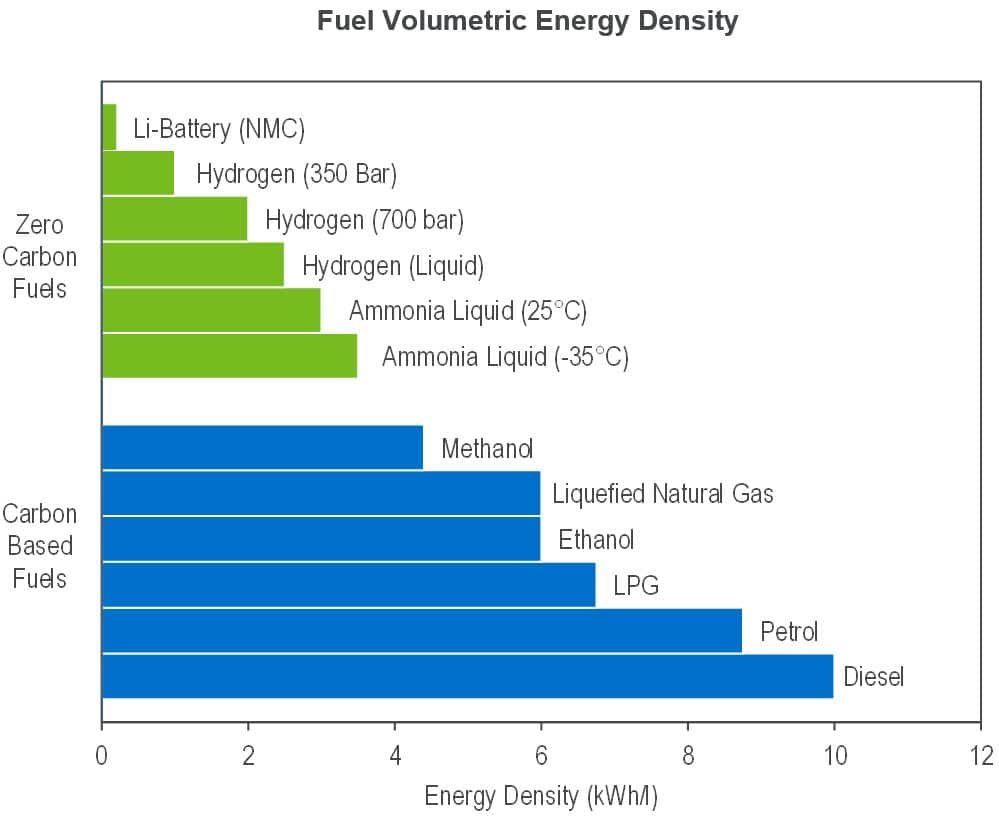

- Energy Density: Ammonia’s lower energy density than traditional fuels may require additional considerations for storage and efficiency, especially for applications requiring high power output.

- Safety Considerations: Ammonia is toxic and corrosive, so storage and handling require careful consideration.

Ammonia and Gasoline Dual-fuel Engine

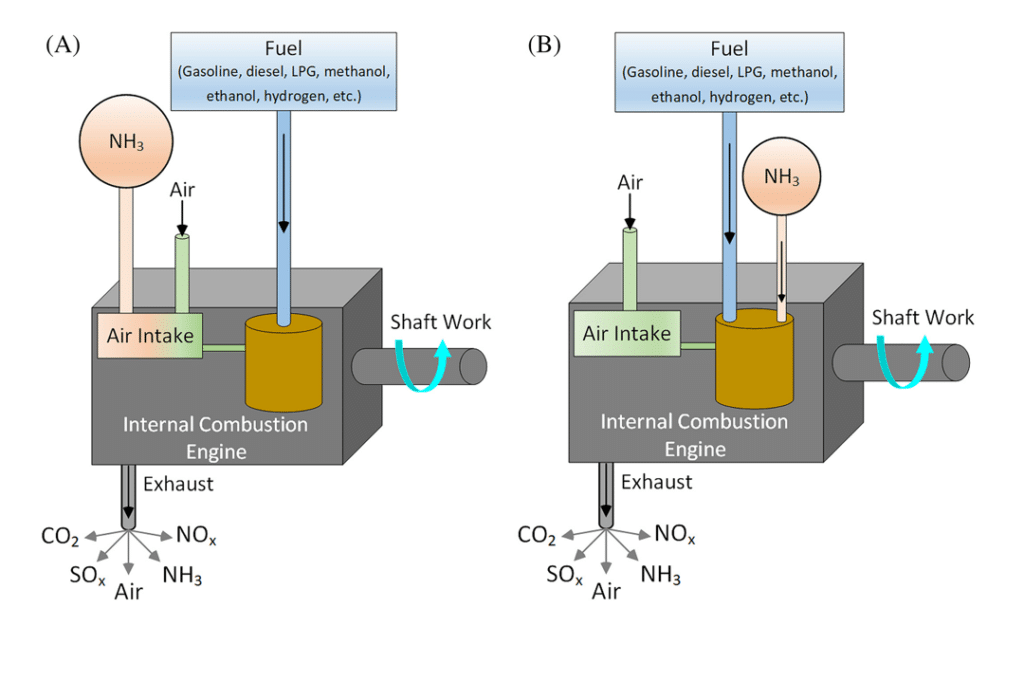

Ammonia dual-fuel engines stem from the need to overcome limitations associated with ammonia’s properties, such as lower energy density. By pairing ammonia with another fuel source that can provide higher power outputs when needed, the dual-fuel engine enhances the usability of ammonia as a vehicle fuel without sacrificing its environmental benefits.

A study in 2022 published in the Journal of Physics underscores this approach, emphasising the feasibility of commercialisation. Much like hybrid vehicles today, dual-fuel engines utilise one fuel type for ignition and regular driving, with the other available for instances requiring more robust power. This approach fortifies the role of ammonia in the automotive landscape, enhancing its potential to be a crucial part of a sustainable transportation future.

What Are the Problems With Ammonia Engines?

While ammonia presents several environmental advantages as a fuel source, it has many unique challenges. Difficult ignition and low flame speeds characterise some technical issues requiring higher compression ratios in engines that utilise ammonia.

Beyond the technical aspects, a broader consideration is the lack of supporting infrastructure and green ammonia production capacity for ammonia engine adoption. These costs remain a barrier, hindering the widespread adoption of ammonia as a mainstream, low-carbon fuel source.

Ammonia Engine Efficiency

Ammonia engines show promising efficiency comparable to traditional fossil fuel engines. A study by Australia’s CSIRO shows that, under various conditions and blends, ammonia-based fuels and engines can sometimes perform with equal or even greater efficiency than their fossil fuel counterparts.

However, comparing efficiency directly can be challenging because efficiency is affected by many variables, such as engine type, operating conditions and specific fuel properties.

Also, the lower energy density of ammonia can necessitate larger fuel storage or more frequent refuelling. While these factors don’t directly impact engine efficiency, they are relevant for the overall efficiency of an ammonia-powered vehicle.

Developments in Ammonia Fuel Engines

The pursuit of ammonia is seeing significant advancements and investments. Researchers, backed by governmental and private funding, are working on overcoming the inherent challenges of the fuel, making it a practical alternative to traditional solutions.

- Technological Innovations: Innovation has been central to ammonia’s development. For example, in 2019, the University of Minnesota made strides in utilising ammonia in internal combustion engines with innovative heat reclamation technology.

- Investment in Research: The global push to decarbonise has led to an increase in research funding. The European Union has committed substantial resources towards green hydrogen and ammonia production, targeting a 55% reduction in greenhouse gas emissions by 2030.

- Collaborations and Partnerships: Various collaborations between industry leaders and academic institutions have fuelled progress. A notable example is the partnership between Siemens Energy and the University of Oxford, which focuses on developing ammonia-based turbines.

- Pilot Projects and Commercialisation: Pilot projects are crucial in transitioning projects from research to real-world applications. The Ammonia-to-Power project in Japan, which aims to generate power by 2024 using ammonia co-firing in coal plants, is an example of commercial-scale implementation.

- Integration with Renewable Sources: Ammonia can be produced with renewables, making it a valuable asset in a sustainable energy future. A noteworthy example is the USD 5 billion green ammonia project in Saudi Arabia, powered entirely by wind and solar energy.

These developments highlight a multidimensional approach to making ammonia a key player in the global energy landscape. By aligning technology, investment, collaborations and real-world applications, a market for ammonia engines is becoming more tangible.

Outlook of Ammonia Engines – Can Ammonia Replace Diesel?

As we venture further into the 21st century, the promise of ammonia engines offers a glimpse into a sustainable transportation future. Ongoing research, commercial implementations and collaboration across sectors are rapidly turning the vision of ammonia-powered transportation into a tangible reality.

While challenges remain, consistent progress and a positive outlook signify a bright future. As we strive for a world less dependent on fossil fuels, the development of ammonia engines opens the door to new possibilities, solidifying its role as a key player in the sustainable energy landscape.

by Eric Koons

Eric is a passionate environmental advocate that believes renewable energy is a key piece in meeting the world’s growing energy demands. He received an environmental science degree from the University of California and has worked to promote environmentally and socially sustainable practices since. Eric’s expertise extends across the environmental field, yet he maintains a strong focus on renewable energy. His work has been featured by leading environmental organizations, such as World Resources Institute and Hitachi ABB Power Grids.

Read more